Andy Norrie

Power consumption is a critical factor in both the design and the purchase of storage devices. Yet it can be hard to measure, especially on an individual device.Traditional methods using an oscilloscope and current probes can be effective but are expensive and hard to implement. A tool that’s specifically designed for drive power testing will give you a much wider range of test options and is much easier to set up. The cost savings of using a purpose-built tool are significant too.

Power consumption is a critical factor in both the design and the purchase of storage devices. Yet it can be hard to measure, especially on an individual device.Traditional methods using an oscilloscope and current probes can be effective but are expensive and hard to implement. A tool that’s specifically designed for drive power testing will give you a much wider range of test options and is much easier to set up. The cost savings of using a purpose-built tool are significant too.

Comparison tests

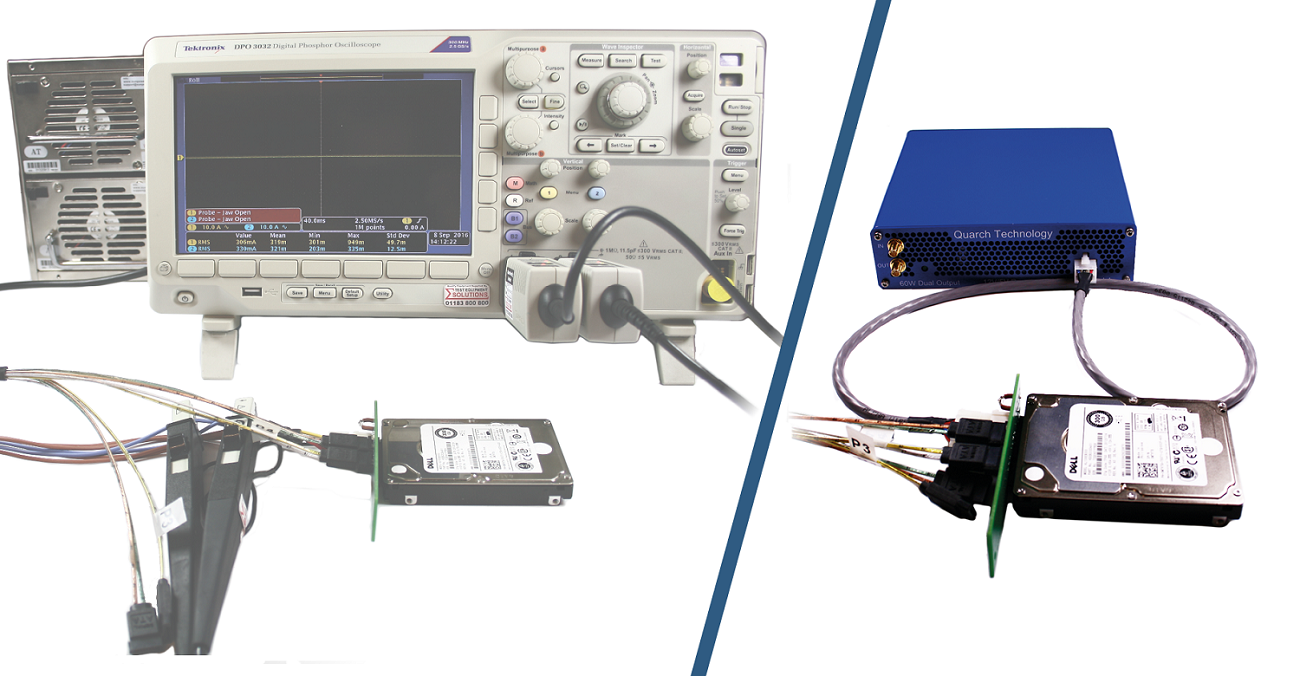

To quantify the difference between using one popular traditional approach and using a purpose-built tool, Quarch set up two key test scenarios in the lab, using:

- A Quarch XLC Programmable Power Module (PPM), and

- A combination of a Tektronix DPO 3032 Oscilloscope and TCP0030 Current Probes.

Each of the above was used to measure:

-

- The average power use of an idle drive over 400 seconds

- Start-up current (the mean and RMS current for 20 seconds, beginning 2 seconds before drive start-up).

The results give a clear comparison of the accuracy and usability of each method.

Oscilloscopes excel at measuring fast signals but aren’t specifically designed for measuring the currents relevant to storage devices. Set-up is complicated and it’s difficult to obtain accurate results or record results for long durations of time.

Quarch power modules solve these problems. In addition, they supply power, allowing you to run a range of extra tests.

The availability of injection fixtures and USB and Ethernet control, with dedicated software, makes running tests both simple and cost-effective.

- Download the Programmable Power Module Vs Scope application note for the full technical details of the comparison tests and results.

- See below for a summary of the advantages of using Quarch power modules.

Why use a purpose-built tool?

One of the main benefits of using Quarch power modules is that they are specifically designed for testing storage devices. They are purpose-built to eliminate the problems associated with traditional testing methods – and therefore perform better.

Some of the various traditional multi-unit testing methods may have a few of the following features; the Quarch power module has all of these:

- Quick, easy set-up – specific power injection fixtures, for 2.5” drives, PCIe cards and M.2 devices, remove the hassle of clamping current probes in awkward places

- The ability to run tests for long periods of time and continuously record power use – ideal when running a drive workload simulation which may last for several hours or longer

- Simple automation – saving engineer time and making testing reliable, repeatable and fast

- Low-current accuracy – Quarch specify measurement down to 100uA, which is accurate at a far lower current than many other devices, and is ideal for measuring low power states

- Fast sampling – up to 250,000 samples per second, faster than a multi-meter or even many expensive Source Measure Units (SMUs)

- Full range, dual rail, power margining – create fast slew-rate custom patterns, from 0V to nominal +20%, allowing for ramps, glitches, brown-out and more, at 1uS resolution

- External triggering – allowing synchronization with third-party equipment (analyzers and similar).

Cost-saving implications

Multiple financial benefits are achievable using the Quarch power module set-up:

- Savings on the initial purchase price, compared to a scope

- Time-savings during the testing process via increased automation

- More accessible power data, allowing you to solve problems earlier.

Initial purchase price

The total cost of an oscilloscope plus probes set-up can be easily three times that of a Quarch XLC PPM. The single-output HD PPM achieves a similar cost-saving, while the multi-port, rack-mounted HD PPM offers further economic advantages if you’re planning automated multi-device power testing.

Time-saving in the testing process

Significant time savings can be made using an automated PPM-based system:

- Save on set-up time

- Run unattended/overnight tests

- Get accurate results faster

- Test up to six devices simultaneously with the multi-port, rack-mounted HD PPM.

As a result, you get your new storage products to market quicker and save on engineering time, leaving your engineers free to focus on designing the next generation of your company’s products.

“Our readers need accurate, comprehensive information about the properties of the drives they buy, so we use Quarch’s power modules to test drive power performance for our SSD reviews. Our testing process is much easier – and even more accurate – since we introduced the Quarch modules, making our SSD reviews even more relevant for our readers.”

Gustav Gager, Nordic Hardware (the largest test lab in Sweden)

Solve problems faster

A scope can capture an image easily, but getting access to power data can be difficult. Using a Quarch PPM gives you easy access to raw data, so you can solve potential problems earlier in your design and testing processes.

Need more information?

- Download the Programmable Power Module Vs Scope application note for the full comparison tests results.

- Find out why test labs, drive reviewers and test equipment manufacturers use Quarch tools – read their comments here.

- Arrange a free evaluation or a quote. Depending on your requirements, we can normally supply you with a free evaluation kit for a short period of time. To apply, or to arrange a quote, email sales@quarch.com or contact one of our skilled regional resellers.